Company News

Samson Makeway Measurement & Control - Semiconductor lead frame appearance inspection case

Manufactured semiconductor products are ubiquitous in our lives, and the slightest mistake in the production process can have irreversible effects. For companies that manufacture semiconductors, the reputation of a product is even more important than the value of the product itself. This is why word of mouth is the decisive criterion for consumers to decide whether or not to buy a manufactured semiconductor product.

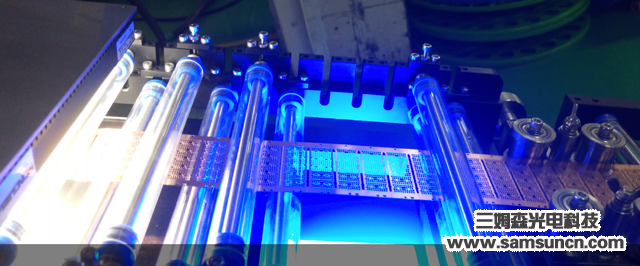

Increasingly complex inspection systems: detection requirements for a variety of products to achieve strong compatibility, the same algorithm function can be two stations to complete the detection requirements, want to complete such a strong compatibility software algorithm is not easy. For visual inspection systems, the compatibility of software algorithms needs to be able to detect the different inspection requirements of different stations, but also to take into account the different inspection speeds of different products for inspection, where the fastest detection speed is 1min/500 stamping (two stations are completed in the case of simultaneous inspection) Samson Makeway Measurement and Control Division (hereinafter referred to as " The intelligent inspection system from Samson Makeway (hereinafter referred to as "Makeway") meets this requirement.

Makeway measurement and control to help you solve the problem

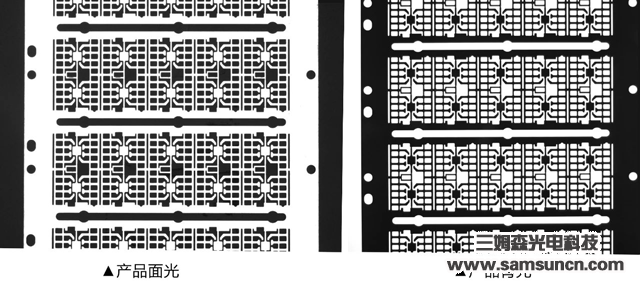

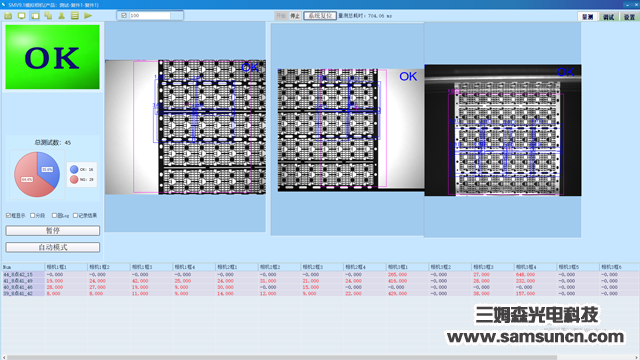

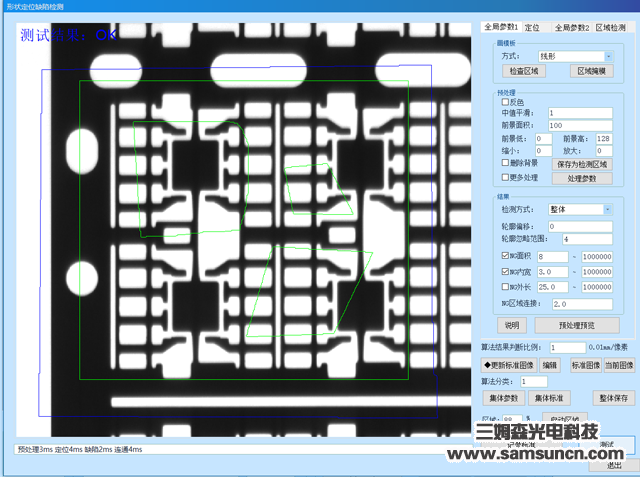

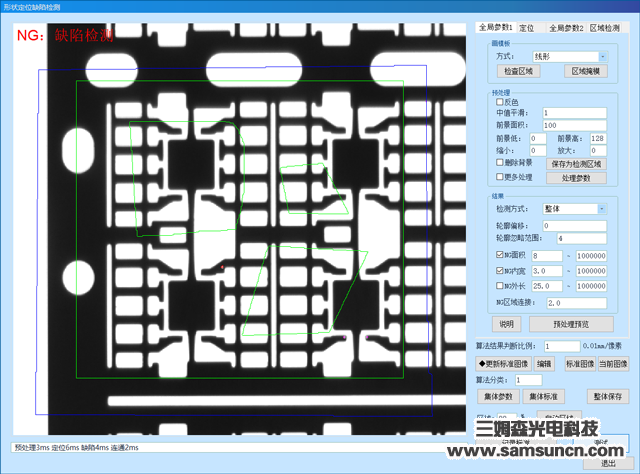

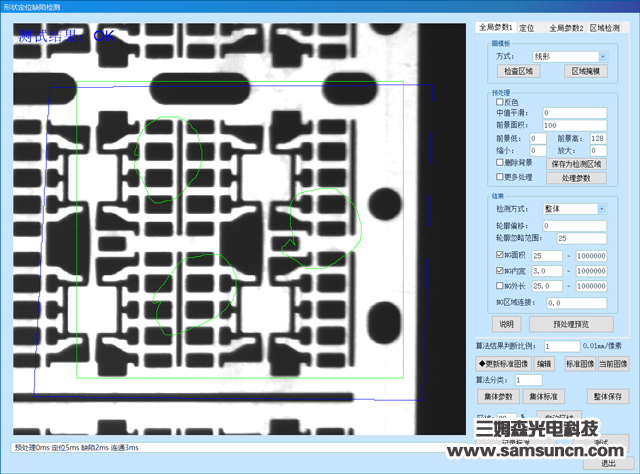

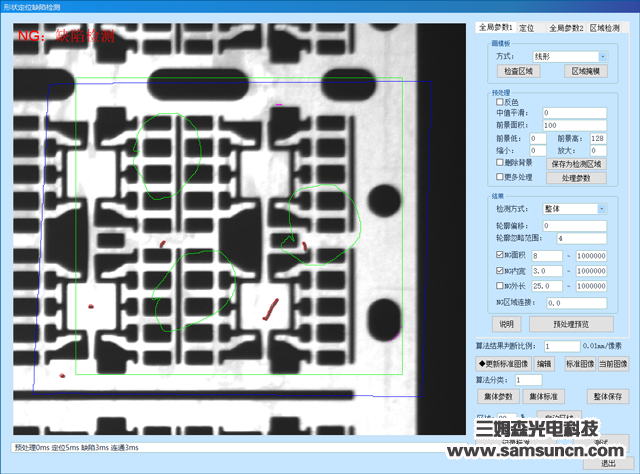

OK Fig. 1 and NG Fig. 1 are face light and detect product crush, matting and scratches. If the product surface has oil stains are not detected as NG, and the detection accuracy is within 0.02mm.

Field test results

With a few sets of pictures and videos, I believe that my friends understand. Companies that develop software from the bottom up, after a long period of technical accumulation and honing, can bring more security and results to their customers. There are millions of systems, and they all have advantages, but what is more important is how we choose a right and reliable, strong company to serve you, is the key.