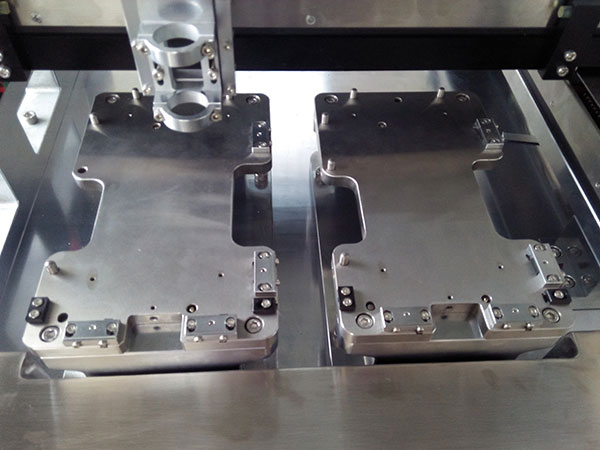

Standard Equipment

SC-190 Series Testing Equipment

- CCD vision inspection, laser measurement, spectral confocal

- Inspection of outline dimensions, flatness, height band differences, thickness of transparent materials, product holes, dimples and bumps, presence of auxiliary materials, etc.

- Measurement of almost all types of materials (metals, glass, ceramics, composites, semiconductors, etc.)

- Inspection accuracy up to ±0.005mm

- Throughput approx. 0.7S/point

Project Requirement

Performance Indicators

Detection Advantage

Equipment Capability

Video Presentation

Samson SC-19 series dispersion confocal intelligent inspection equipment a full range of intelligent inspection solutions, widely used in 3C, machinery, moulds and other manufacturing fields, more than ten years of experience in the optical application inspection industry.

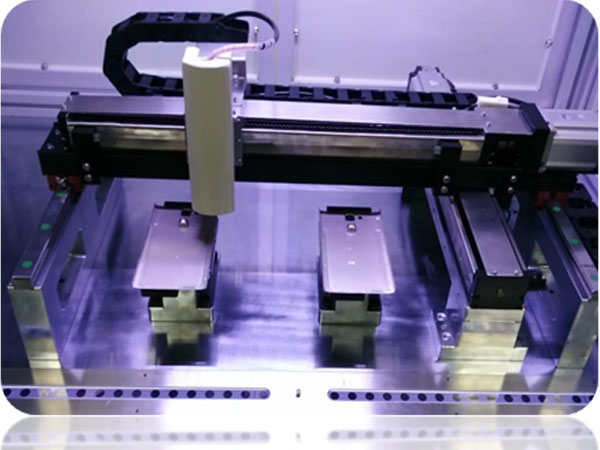

Can achieve point, line, circle, arc, angle, distance, ellipse, angle, contour degree and other graphics of one-touch rapid measurement, high accuracy, versatility, easy operation; data traceability

Measurement of almost all types of materials (MIM parts, small metal parts, glass covers, ceramics, 3D composites, semiconductors, etc.) Flatness/height segment difference/transparent material thickness/product hole position, external dimensions/profile/concave and convexity/existence of auxiliary materials, etc.

Inspection accuracy: 0.005~0.01mm; Inspection speed: spectral part approx. 0.7 sec/point; line laser approx. 0.3 m/sec

| Model | SC-1910 | SC-1911V | SC-1911L | |

| Equipment name | High precision dispersion confocal intelligent inspection equipment | |||

| Detection function | Flatness / height band difference / thickness of transparent material | Flatness/height difference/thickness of transparent material/hole position of the product/bumpy table/availability of accessories, etc. | Flatness/height band difference/thickness | |

| Software | Samsun SMV vision inspection software | Samsun SLM vision inspection software | Samson SC Confocal Spectroscopy Inspection Software + Samson SML Laser Inspection Software | |

| Detection accuracy | ≤0.005mm | ≤0.005mm | ≤0.005mm | |

| Testing features | High precision, suitable for small steps and all material surfaces |

Improved positioning accuracy through vision positioning

Vision can also measure product features individually

|

Combining the accuracy of point spectroscopy with the high speed of line laser measurement | |

| Production capacity | Approx. 0.7S/point | Spectral component approx. 0.7 sec/point, visual depending on specific imaging requirements | Spectral section approx. 0.7 sec/point, line laser approx. 0.3 m/s | |

| Main configuration measurement methods | Guide rails | Imported precision guide rails | ||

| Spectrometers | Imported spectral emitter, resolution 20nm | |||

| Processing controllers | Imported spectral matching processing controller | |||

| Loading and unloading method | Pallet/manual/manipulator | Pallet/manual/manipulator | Pallet/manual/manipulator | |

| Detection method | Spectral sensor movement automatically completes detection | |||

| Inspection stations | Spectrum*1 | Spectrum*1+CCD*1 | Spectrum*1+Laser*1 | |

| Number of products measured simultaneously | 1PCS | 1PCS | 1PCS | |

| Dimensions | 1200*1000*1700mm | |||

| Weight | 300kg | |||

| Working environment | Temperature: 20°±2° (no dew point) Humidity: 30~80% | |||

| Voltage | 220V | |||