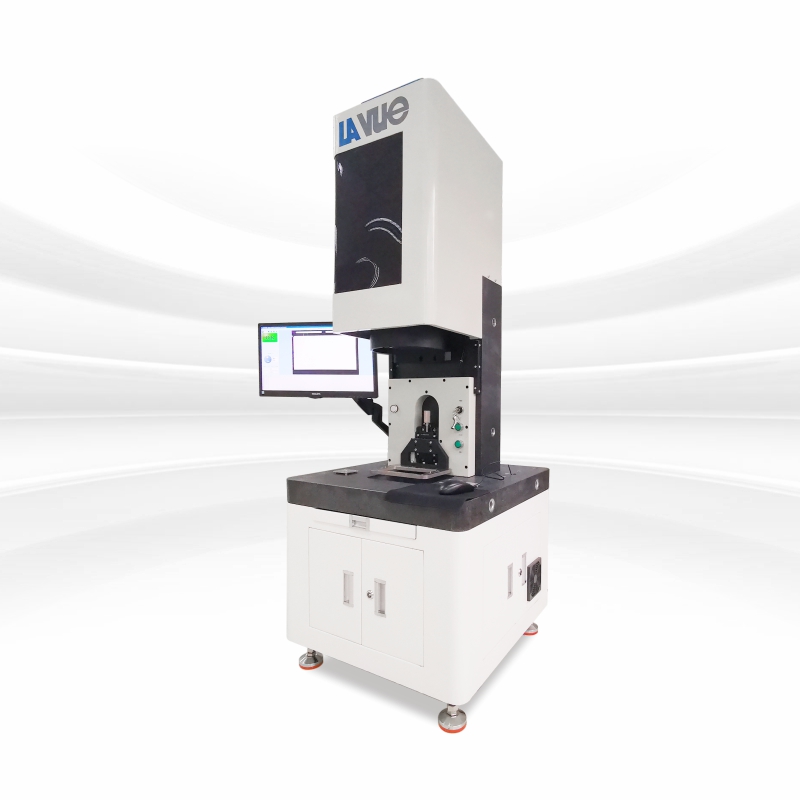

Standard Equipment

CV-100 Series Testing Equipment

- CCD vision inspection

- Measurement of distance, radius, angle, curvature, position, perpendicularity and other dimensional inspection and character defect detection

- Suitable for 3D composite materials, glass covers, various metal products

- Inspection accuracy up to ±0.005mm

Project Requirement

Performance Indicators

Detection Advantage

Equipment Capability

Video Presentation

The CV-100 series of Samson one-touch measuring equipment uses vision inspection technology, and after setting up the program, simply press the measuring button to achieve one-touch rapid measurement; it has strong versatility and ease of use characteristics, and can achieve all kinds of metal, 3D composite materials, glass cover type products in the XY direction of the shape size, hole size, contour size of rapid measurement, to achieve multi-directional quality control The result is a multi-faceted quality control.

- Highly versatile, accurate flash measurements, no individual differences in results

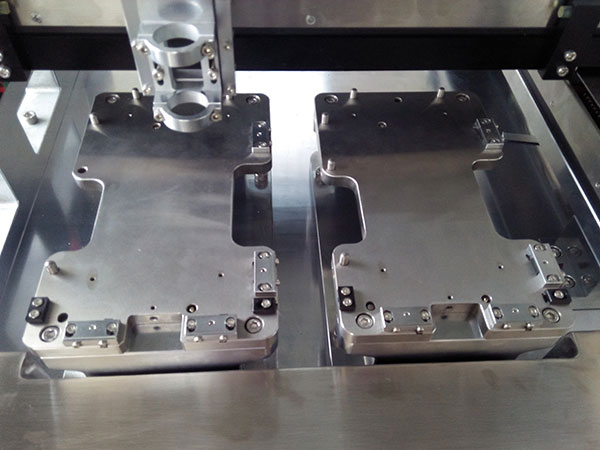

- automatic image matching function, the measuring workpiece can be placed in any position, no positioning fixture, no focus adjustment, no manual operation of the load table.

- Measurement accuracy of 5μm, repeatability of 1μm

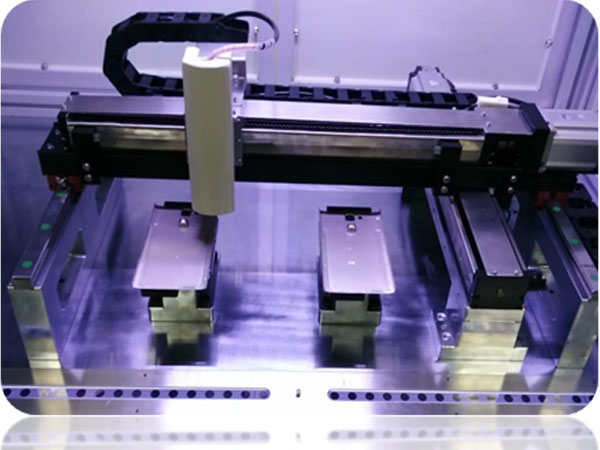

- multiple positions of the workpiece can be measured, increasing the size of the measurement without additional measurement time.

- Multiple workpieces can be measured together at the same time, eliminating the need for individual measurements for each workpiece.

- Easy operation, fast completion of all measurement processes and output of results; clear image focus within 2 seconds, repeatable focus consistency and zero errors

- No stage movement during measurement, effectively preventing measurement errors caused by product displacement.

- Anti-vibration table design and one-piece construction to ensure the rigidity of the instrument.

- Ergonomic design for a comfortable measuring space.

- automatic saving of measurement results to the mainframe.

| Model | CV-100L | CV-100M |

| Equipment name | High precision one-touch measuring and visual inspection equipment | High-precision, compact one-touch vision inspection equipment |

| Detection function | Inspection of 3D composite materials, glass covers and various metal products in the XY-direction for form and hole dimensions | Inspection of the external dimensions and contour dimensions of various small metal parts in the XY direction |

| Software | Samsun SMV vision inspection software | Samsun SMV vision inspection software |

| Equipment calibration accuracy | 0.005mm | 0.005mm |

| Testing features | One-touch rapid measurement of points, lines, circles, arcs, angles, distances, ellipses, angles, contours and other shapes with high accuracy and versatility | One-touch rapid measurement of points, lines, circles, arcs, angles, distances, ellipses, angles, contours, etc., with high accuracy, versatility and compactness |

| Production capacity | 1 PCS/S | 1 PCS/S |

| Cameras | 29 megapixel resolution industrial camera | 25 megapixel resolution industrial camera |

| Footage | Double-sided telecentric high-depth-of-field industrial lens (moving maximum depth-of-field 200MM) | Double-sided telecentric high-depth-of-field industrial lens (moving maximum depth of field 100MM) |

| Light source | High brightness industrial LED backlighting | High brightness industrial LED backlighting |

| Processing controllers | Industrial grade image processors | Industrial grade image processors |

| Loading and unloading method | Manual loading and unloading | Manual loading and unloading |

| Detection method | CCD vision inspection | CCD vision inspection |

| Inspection stations | Single station | Single station |

| Number of products measured simultaneously | Single or multiple (optional) | Single or multiple (optional) |

| Dimensions | 750*700*1900mm | 350*500*700mm |

| Weight(kg) | 150 | 30 |

| Working environment | Temperature: 20°±2° (no dew point) Humidity: 30~80% | Temperature: 20°±2° (no dew point) Humidity: 30~80% |

| Voltage | 220V |

220V |