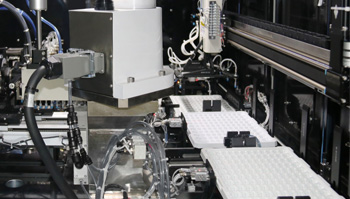

Samson 3C product assembly AOI inspection

Software developed in-house to quickly identify all types of defects and provide accurate measurements for 3C electronics

A range of quality inspection requirements such as mobile phone seams, auxiliary materials, internal view of laptops, keyboard defect detection, etc.

Samson testing equipment will meet all of these requirements

Measures almost all types of materials (metals, glass, ceramics, composites, semiconductors, etc.)

Inspection products: almost all types of materials can be measured (MIM parts, various small metal parts products, glass covers, ceramics, 3D composites, semiconductors, etc.)

Inspection products: almost all types of materials can be measured (MIM parts, various small metal parts products, glass covers, ceramics, 3D composites, semiconductors, etc.) Inspection functions: flatness/height difference/thickness of transparent material/hole position of product, external dimensions/profile/concave and convexity/absence of accessories, etc.

Inspection functions: flatness/height difference/thickness of transparent material/hole position of product, external dimensions/profile/concave and convexity/absence of accessories, etc. Detection accuracy: 0.005~0.01mm

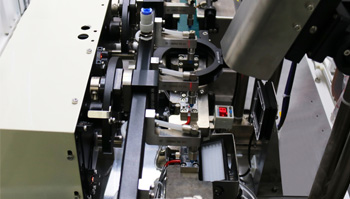

Detection accuracy: 0.005~0.01mm Main measurement method: CCD visual inspection + laser measurement + spectral confocal

Main measurement method: CCD visual inspection + laser measurement + spectral confocal Production capacity approx. 0.7S/point

Production capacity approx. 0.7S/point Detecting products: suitable for a variety of high-precision metal small parts; universal, can be used to detect a variety of similar products when not moving the hardware.

Detecting products: suitable for a variety of high-precision metal small parts; universal, can be used to detect a variety of similar products when not moving the hardware. Inspection functions: product dimension, flatness, height/thickness dimension measurement.

Inspection functions: product dimension, flatness, height/thickness dimension measurement. Inspection accuracy: up to ±0.005mm.

Inspection accuracy: up to ±0.005mm. Main measurement method: CCD visual inspection + laser measurement.

Main measurement method: CCD visual inspection + laser measurement. Production capacity up to 3500PCS/H

Production capacity up to 3500PCS/H Inspection products: Suitable for mobile phone buttons, camera rings, card holders, Type-C connectors, paper clips, connectors and other metal precision machined parts, small parts of medical devices, small plastic parts, etc.

Inspection products: Suitable for mobile phone buttons, camera rings, card holders, Type-C connectors, paper clips, connectors and other metal precision machined parts, small parts of medical devices, small plastic parts, etc. Inspection functions: Product outline size, flatness, position, height difference, cosmetic defects, etc.

Inspection functions: Product outline size, flatness, position, height difference, cosmetic defects, etc. Inspection accuracy: up to ±0.005mm

Inspection accuracy: up to ±0.005mm Main measurement method: CCD visual inspection + laser measurement

Main measurement method: CCD visual inspection + laser measurement Production capacity up to 3600PCS/H

Production capacity up to 3600PCS/H Products tested: for 3D composites, glass covers, various metal products

Products tested: for 3D composites, glass covers, various metal products Inspection functions: measurement of distances, radii, angles, radians and other dimensions

Inspection functions: measurement of distances, radii, angles, radians and other dimensions Inspection accuracy up to ±0.005mm

Inspection accuracy up to ±0.005mm Main measurement method: CCD visual inspection

Main measurement method: CCD visual inspection Testing features: universal equipment, accurate flash measurements, no differences in measurement results from one person to another

Testing features: universal equipment, accurate flash measurements, no differences in measurement results from one person to another Products tested: 3D composite materials, mobile phone back covers, glass back covers, mobile phone mid-frames, camera mounts, watch structural parts, rechargeables, 5G ceramics, etc.

Products tested: 3D composite materials, mobile phone back covers, glass back covers, mobile phone mid-frames, camera mounts, watch structural parts, rechargeables, 5G ceramics, etc. Inspection functions: external dimensions, height dimensions, flatness, perpendicularity inspection

Inspection functions: external dimensions, height dimensions, flatness, perpendicularity inspection Inspection accuracy up to ±0.005mm

Inspection accuracy up to ±0.005mm Main measurement method: CCD visual inspection + laser measurement

Main measurement method: CCD visual inspection + laser measurement Production capacity up to 550PCS/H

Production capacity up to 550PCS/HReal-time image acquisition, production data screen display query output, printout, can be docked to the production management software

Repeatability can be measured and evaluated periodically by yourself and records can be kept, and inspection accuracy can be effectively maintained.

Production report output, data storage for defective product analysis, process improvement

Simple and economical system structure, effectively reducing production and maintenance costs

Simple and economical system structure, effectively reducing production and maintenance costs

Effective automation to improve production efficiency, reduce defective rates, reduce rework and waste

Effective automation to improve production efficiency, reduce defective rates, reduce rework and waste

Increase labour productivity, improve core competencies, win a wide range of customers and obtain orders

Increase labour productivity, improve core competencies, win a wide range of customers and obtain orders

Substitution of manual labour, with significant savings in labour and safety costs

Substitution of manual labour, with significant savings in labour and safety costs

Product quality is improved while freeing workers from tedious labour

Product quality is improved while freeing workers from tedious labour

Automated, efficient and accurate, low misjudgment, multi-measurement integration, easy to operate, digital

Learn about the application of3C product assembly AOI inspectionin production with a one-minute video

Please fill in your personal information, we will get in touch with you as soon as possible